Top 5 Essential Control Systems for Optimizing Industrial Automation

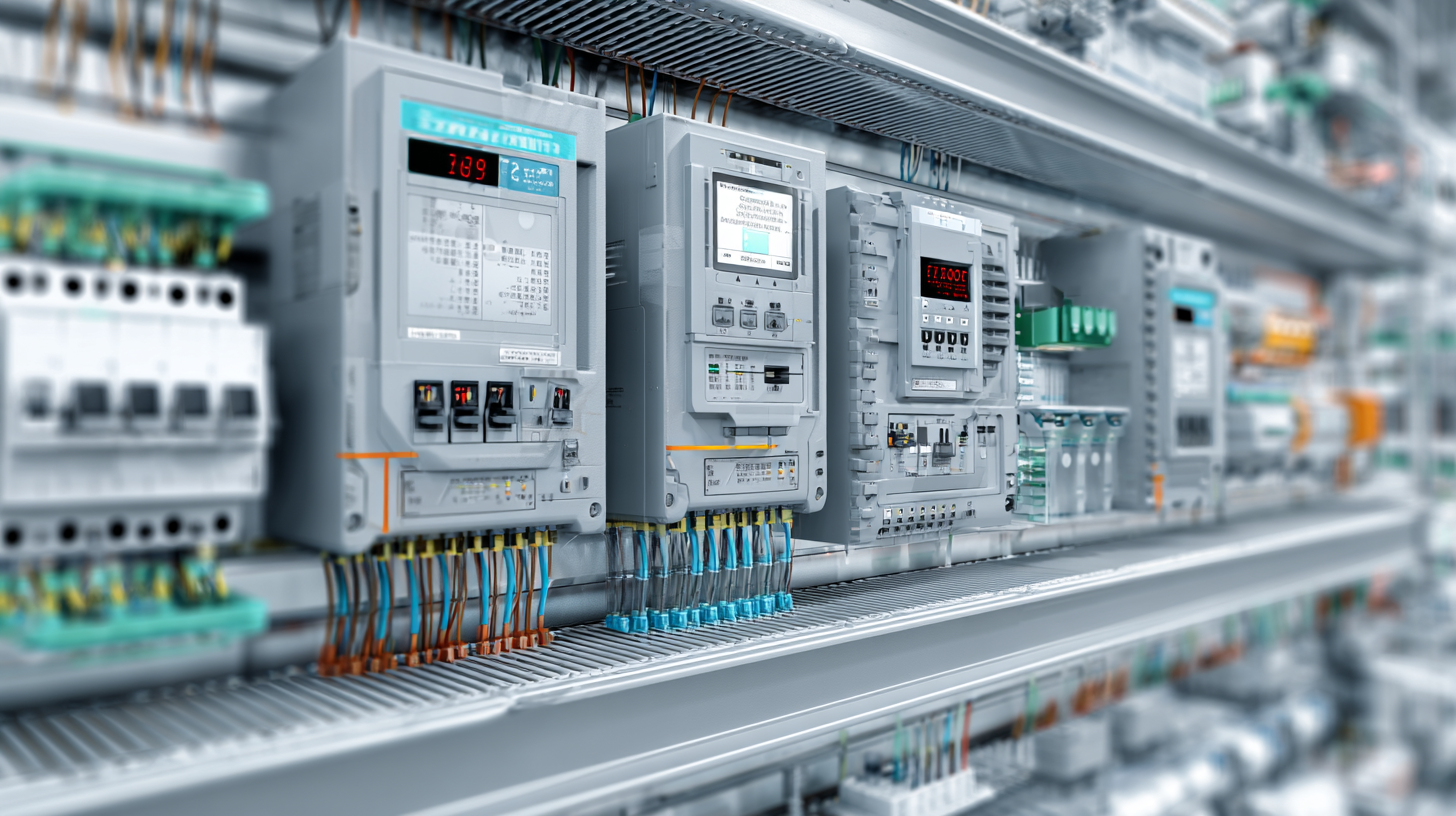

In the rapidly evolving landscape of industrial automation, the importance of efficient control systems cannot be overstated. These systems serve as the backbone of modern manufacturing processes, enabling companies to streamline operations, enhance productivity, and maintain competitive advantages in a global market. As industries increasingly turn to automation to meet growing demands, understanding the fundamental control systems that drive these advancements becomes essential.

This article delves into the top five control systems that play a pivotal role in optimizing industrial automation. By exploring their unique functionalities and applications, we can gain insights into how these systems not only facilitate better monitoring and management of industrial processes but also drive innovation within the sector. From PLCs to SCADA and more, each control system is designed to address specific challenges faced by manufacturers, ensuring they remain agile and efficient in a constantly changing environment. Through this exploration, we aim to highlight the critical role that these control systems play in supporting and advancing industrial automation.

Key Features of Advanced Control Systems in Industrial Automation

In the realm of industrial automation, advanced control systems play a pivotal role in enhancing efficiency and productivity. One of the key features of these systems is their ability to utilize real-time data analytics. By continuously monitoring parameters such as temperature, pressure, and flow rates, these systems make instant adjustments to ensure optimal operation. This not only minimizes wastage but also significantly reduces downtime, leading to a more streamlined production process.

Tips: When selecting a control system, ensure it supports seamless integration with existing machinery. This compatibility will facilitate smoother operations and save time and resources.

Another essential feature of advanced control systems is their sophisticated user interface, which provides operators with intuitive controls and visualization tools. These interfaces are designed to simplify complex data presentation, allowing for quick decision-making and response to any anomalies within the workflow.

Tips: Regular training for operators on these interfaces can greatly enhance operational efficiency and help in leveraging the system’s full potential.

Top 5 Essential Control Systems for Optimizing Industrial Automation

| Control System | Key Features | Advantages | Applications |

|---|---|---|---|

| PID Controller | Simple, reliable, and widely used | Easy to implement and tune | Temperature control, speed control |

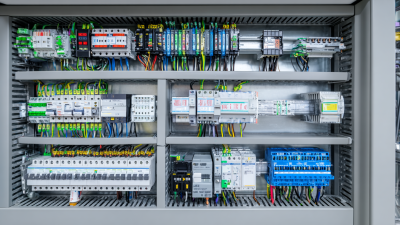

| PLC (Programmable Logic Controller) | Versatile and programmable | Flexible in configuration and easy debugging | Manufacturing lines, assembly processes |

| DCS (Distributed Control System) | Centralized control with distributed elements | Enhanced reliability and scalability | Chemical plants, water treatment facilities |

| SCADA (Supervisory Control and Data Acquisition) | Real-time monitoring and control | Data analysis and operational visibility | Utilities management, energy distribution |

| FCS (Factory Control System) | Integrates with manufacturing operations | Optimizes production efficiency | Assembly lines, automated factories |

Comparative Analysis of PID and Fuzzy Logic Control Techniques

In the realm of industrial automation, two prominent control techniques stand out: Proportional-Integral-Derivative (PID) control and Fuzzy Logic control. PID controllers, established as a standard in various industries, provide precise control by adjusting the output based on the error between a desired setpoint and a measured process variable. According to a report by MarketsandMarkets, the global PID controller market was valued at approximately $900 million in 2021 and is projected to grow at a CAGR of over 6% through 2026, highlighting their continued relevance in optimizing process control.

On the other hand, Fuzzy Logic control offers a more adaptive approach, particularly in systems characterized by uncertainty and imprecision. Unlike the rigid framework of PID controllers, Fuzzy Logic mimics human reasoning and can handle complex variables more effectively. A study from the International Journal of Advanced Manufacturing Technology suggests that Fuzzy Logic systems can improve response time and accuracy in dynamic environments by as much as 30% compared to traditional PID setups. As industries increasingly adopt advanced automation technologies, understanding the comparative advantages of these control techniques becomes essential for enhancing operational efficiency and decision-making in complex environments.

Comparison of Control Systems for Industrial Automation

This chart compares the effectiveness of various control techniques in optimizing industrial automation processes. The metrics used for comparison are stability, responsiveness, ease of tuning, and adaptability.

Impact of SCADA Systems on Real-Time Monitoring and Control

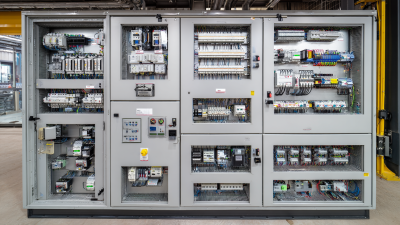

In today's fast-paced industrial landscape, SCADA (Supervisory Control and Data Acquisition) systems play a vital role in real-time monitoring and control. These systems enable operators to manage processes remotely, enhancing efficiency and reducing the risk of human error. By collecting and processing large volumes of data from various sensors and devices, SCADA systems provide a comprehensive view of operations, allowing for quick decision-making.

Tip: When implementing SCADA systems, ensure they are integrated with existing legacy systems to maximize their potential. This integration can prevent data silos and ensure seamless communication across different departments, leading to improved operational efficiency.

Moreover, SCADA systems offer advanced reporting and analytical capabilities. By utilizing these features, companies can identify trends, anticipate maintenance needs, and optimize their processes. The real-time data visualization provided by SCADA systems helps in detecting anomalies swiftly, allowing organizations to respond proactively.

Tip: Regularly update training for staff on SCADA functionalities. Empowering your team with the latest knowledge ensures they can fully leverage the system's capabilities, ultimately leading to better performance and reduced downtime.

Integration of IoT in Modern Control Strategies for Industry

The integration of the Internet of Things (IoT) into modern control strategies is revolutionizing industrial automation. As industries increasingly rely on connected devices for real-time data collection and processing, the global market for wireless industrial IoT sensors is projected to reach approximately $7.973 billion by 2025, with remarkable growth anticipated to nearly $21.498 billion by 2033. This represents a compound annual growth rate (CAGR) of 13.2%, highlighting the accelerating pace at which businesses are adopting these advanced technologies.

Moreover, the IoT chip market exhibits significant potential, forecasted to expand from approximately $68.58 billion in 2025 to over $166.63 billion by 2032, marking a robust CAGR of 13.5%. This growth is driven by the increasing demand for microcontroller units (MCUs), which serve as the backbone of countless devices, enabling essential functions such as control, sensing, and communication across various sectors. The application of AI and IoT in industrial processes is not just a trend but a crucial strategy for manufacturers aiming to enhance operational efficiency and remain competitive in the evolving marketplace.

Future Trends: AI and Machine Learning in Control System Optimization

The integration of AI and machine learning with digital twin technology is revolutionizing control systems in industrial automation. By creating a virtual representation of physical assets, digital twins enable enhanced simulation and high-resolution modeling, making precise manufacturing processes not only feasible but also efficient. This technology plays a crucial role in innovative applications such as product design, where real-time adjustments can significantly reduce development time and costs. Moreover, the synergy of AI and digital twins is pushing industries towards self-optimizing systems that adapt to changing environments seamlessly.

Tips: When implementing digital twins, ensure that the data used for modeling is accurate and up-to-date. This will enhance the reliability of the simulations and lead to better decision-making. Additionally, consider investing in training staff to effectively use AI tools, which can further enhance productivity and innovation.

As we enter the era of 5.5G, the evolution of AI will bring forth new application scenarios. The increasing demands on 5.5G networks will highlight the importance of AI in addressing connectivity challenges and optimizing resource allocation. Reinforcement learning, for instance, is already showing remarkable results, such as the increased speed of robotic systems. Adapting to these future trends will ensure companies stay competitive in the fast-evolving landscape of industrial automation.

Related Posts

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

-

The Rise of Control Cubicles in Modern Workspaces Enhancing Productivity and Employee Satisfaction

-

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing

-

How to Master PLC Controller Programming for Industrial Automation