7 Essential Tips for Creating the Best Control Panel Drawings in Industrial Automation

In the realm of industrial automation, precise and well-structured control panel drawings are essential for ensuring seamless operations and maintenance efficiency. According to a report by the International Society of Automation (ISA), over 70% of automation projects experience delays due to inadequate documentation and unclear control panel schematics. As industries increasingly rely on complex control systems, the demand for high-quality, standardized control panel drawings has skyrocketed. Properly crafted drawings not only facilitate clearer communication among engineers, technicians, and stakeholders but also play a critical role in compliance with safety regulations and operational standards.

This blog will outline seven essential tips to help you create the best control panel drawings that meet industry benchmarks and enhance automation efficiency.

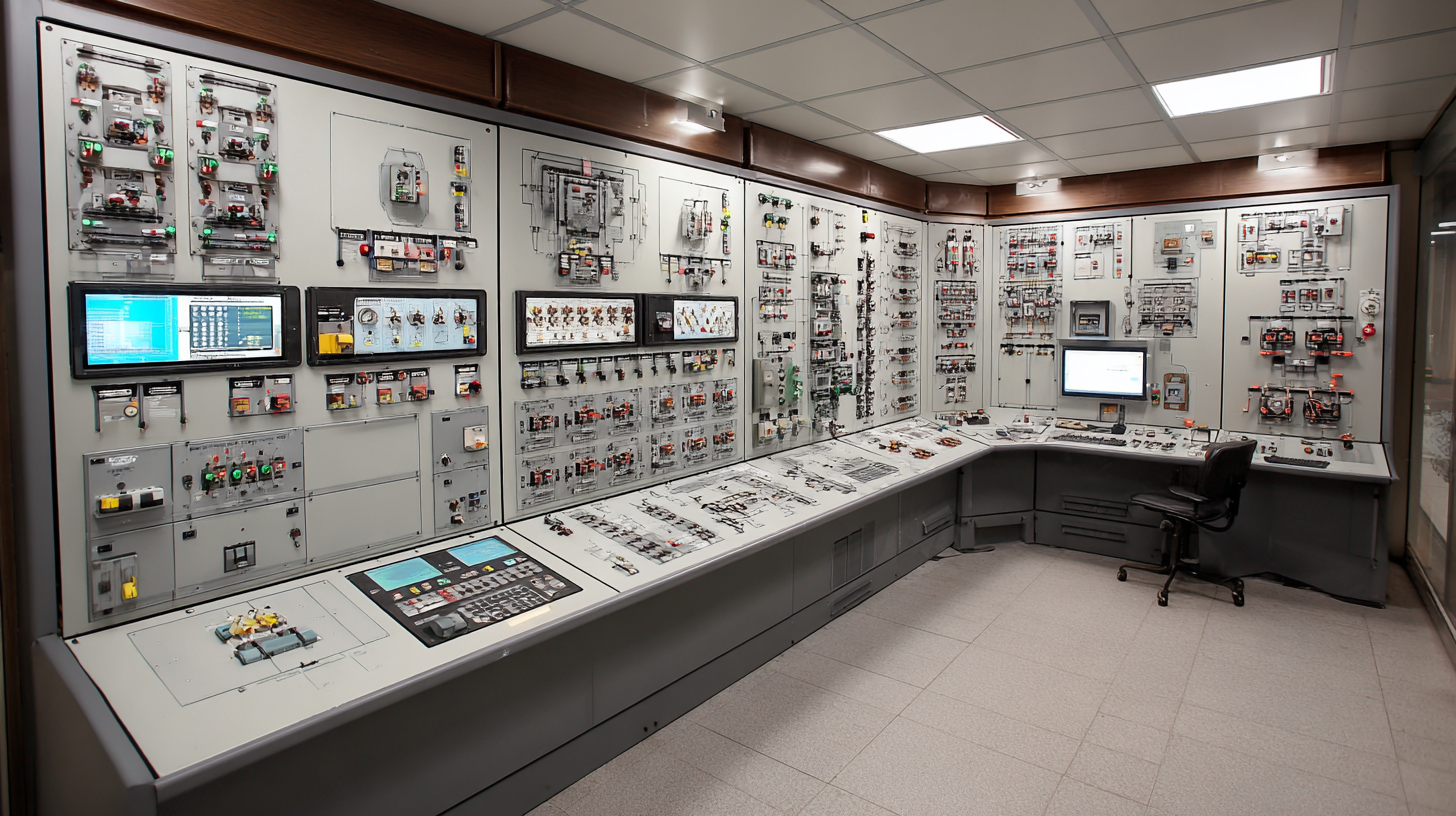

Key Principles of Control Panel Layout for Optimal Space Utilization

In the realm of industrial automation, an optimized control panel layout is crucial for efficient operation and maintenance. According to a recent report by the International Society of Automation, nearly 30% of downtime in manufacturing facilities can be attributed to inadequately designed control panels. To combat this issue, focusing on space utilization is imperative.

One effective strategy is to prioritize component arrangement by functional purpose, ensuring that frequently accessed devices are placed within easy reach. This minimizes unnecessary movement and streamlines operations. Additionally, adhering to proper spacing standards can prevent overheating and promote airflow, greatly enhancing the longevity of electronic components.

Another key consideration is the use of modular design elements, which provide flexibility for future expansions or modifications. A structured layout, including organized wiring and clear labeling, not only improves the panel’s accessibility but also simplifies troubleshooting processes. Research from the Automation Federation indicates that companies employing these best practices experienced a 25% reduction in maintenance time, demonstrating the significant impact of thoughtful control panel design on operational efficiency.

7 Essential Tips for Creating the Best Control Panel Drawings in Industrial Automation

| Tip Number | Essential Tip | Description | Benefits |

|---|---|---|---|

| 1 | Organized Layout | Design a clear and logical arrangement of components | Enhances ease of maintenance and troubleshooting |

| 2 | Adequate Space | Ensure sufficient spacing between components | Prevents overheating and allows for easy access |

| 3 | Standardized Symbols | Use industry-standard electrical symbols | Improves communication among engineers and technicians |

| 4 | Labeling | Clearly label each component and connection | Facilitates quick identification and troubleshooting |

| 5 | Safety Considerations | Incorporate safety features and clearances | Reduces risk of electrical hazards and accidents |

| 6 | Cable Management | Organize and secure wires and cables | Prevents interference and simplifies future modifications |

| 7 | Documentation | Provide thorough drawings and manuals | Ensures proper installation and future reference |

Understanding Standard Electrical Symbols in Control Panel Drawings

In the realm of industrial automation, the importance of standard electrical symbols in control panel drawings cannot be overstated. These symbols serve as a universal language that facilitates clear communication among engineers, technicians, and operators. By adhering to these standards, the complexity of electrical schematics is simplified, enabling quick understanding and reducing the chances of errors during installation and maintenance.

Understanding these symbols is essential for anyone involved in design or assembly. Common symbols include those for switches, relays, and circuit breakers, each representing specific functions and characteristics. When creating control panel drawings, utilizing these standardized symbols ensures that the drawings are not only accurate but also easily interpretable by others in the field. This practice not only streamlines the workflow but also enhances safety by minimizing misunderstandings in high-stakes environments where precise control is critical.

Integrating these symbols effectively into your drawings can lead to more efficient project execution and ultimately contribute to the success of industrial automation endeavors.

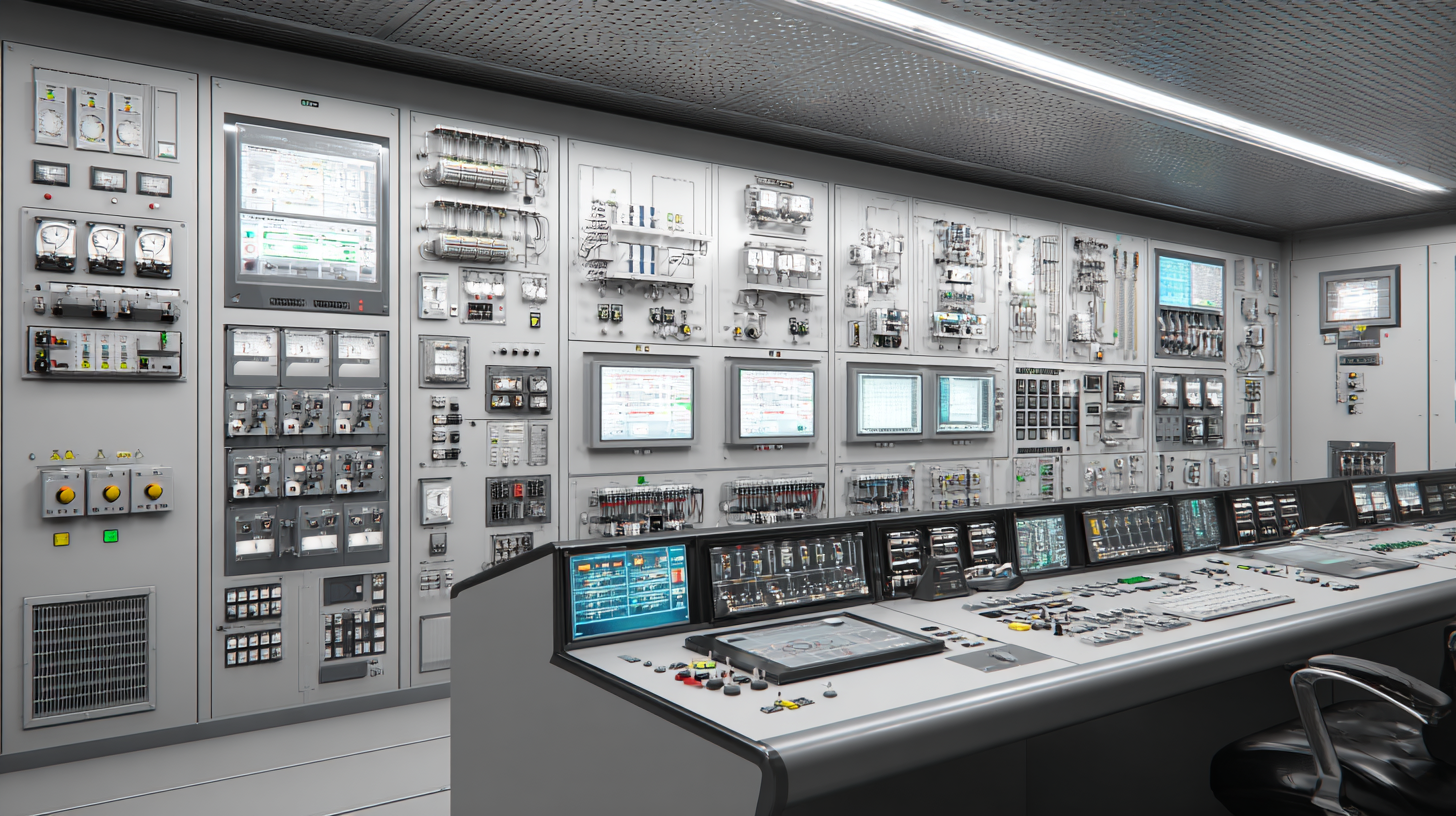

Incorporating Safety Standards and Regulations in Control Panel Design

In the realm of industrial automation, designing control panels requires meticulous attention to safety standards and regulations. These guidelines not only serve to protect the personnel operating within these environments but also ensure the machinery functions seamlessly without causing hazards. Incorporating safety measures into control panel designs involves understanding industry-specific regulations, such as those set forth by ANSI, NFPA, or IEC. By adhering to such standards, engineers can implement features like emergency shut-off switches, proper labeling of components, and clear wiring practices that facilitate easy troubleshooting and maintenance.

Moreover, the use of modern technology can greatly enhance safety within control panels. Integrating advanced monitoring systems allows for real-time assessments of equipment status, helping identify potential failures before they escalate into serious issues. The incorporation of digital tools and simulations can also aid in ensuring compliance with safety standards during the design phase. Ultimately, a robust safety-centric approach in control panel design not only mitigates risks but also contributes to the overall reliability and efficiency of industrial automation systems.

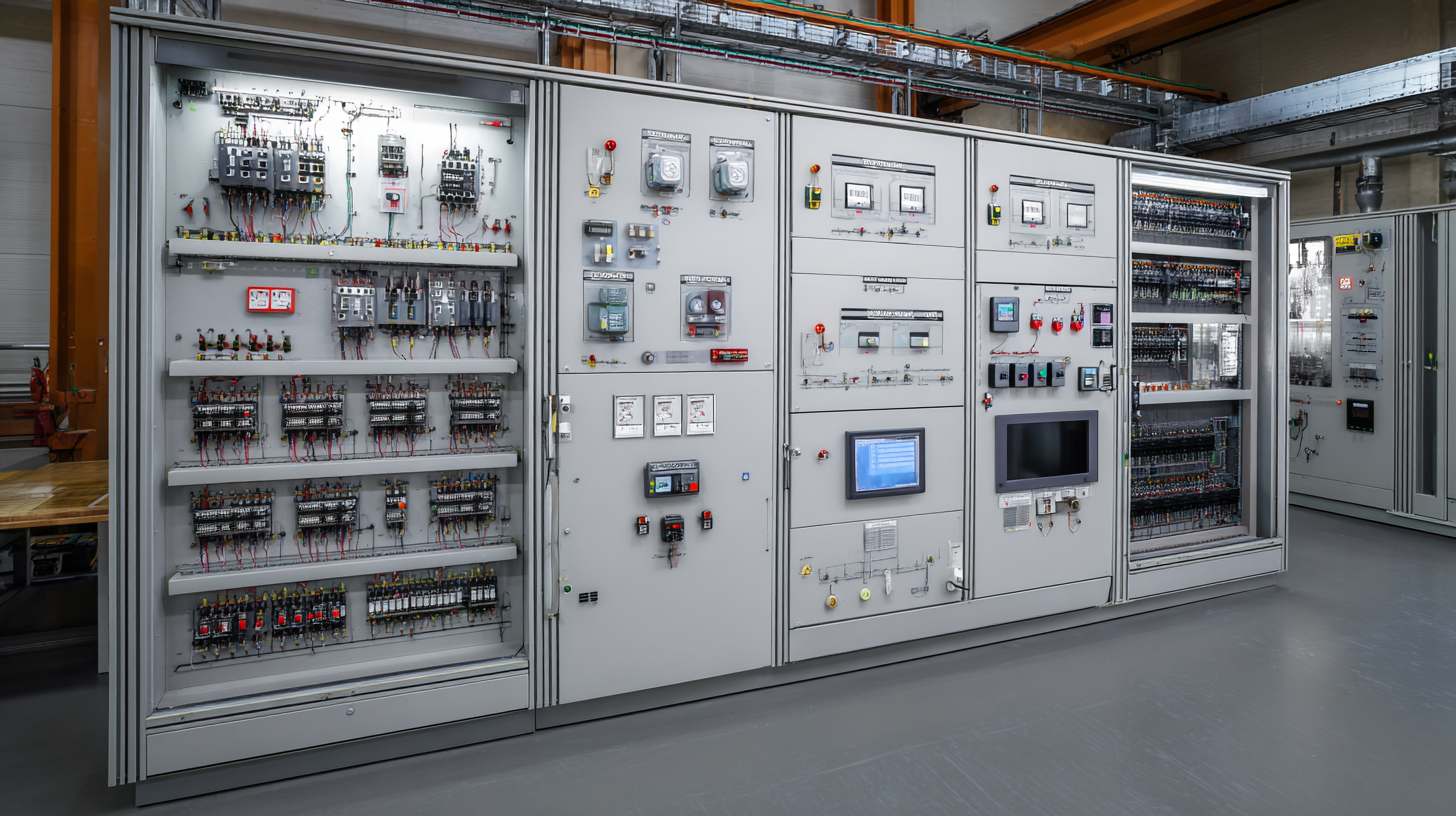

Leveraging Software Tools for Enhanced Accuracy in Control Panel Drawings

In the realm of industrial automation, accuracy in control panel drawings is crucial for the seamless operation of systems. Leveraging software tools can significantly enhance precision, ensuring that drawings meet both regulatory standards and operational requirements. Advanced software solutions, such as CAD programs, enable engineers to create detailed schematics with ease. These tools often come equipped with libraries of components and symbols that adhere to industry standards, which helps in minimizing errors associated with manual drafting.

Moreover, utilizing 3D modeling software allows design teams to visualize the control panel layout and interactions between various components before physical assembly occurs. This proactive approach helps in identifying potential design flaws early in the process, ultimately saving time and resources. The ability to simulate electrical flows within the software also provides insights into performance, making it easier to optimize designs for efficiency. As industrial automation continues to evolve, embracing these software tools is essential for engineers aiming to produce the best control panel drawings, ensuring operational excellence and safety.

Best Practices for Documentation and Revision Control in Automation Projects

In the fast-paced world of industrial automation, maintaining effective documentation and revision control is paramount. Accurate control panel drawings ensure that all stakeholders are on the same page, minimizing errors and enhancing project timelines. One essential tip is to implement a clear versioning system. This allows team members to track changes easily, ensuring that the latest drawings are always utilized in the field.

Another vital practice is to utilize standardized symbols and formats across all documentation. This consistency not only simplifies understanding for new team members but also streamlines the communication process with external partners. Moreover, regularly scheduled reviews of documentation can help identify potential discrepancies before they lead to costly mistakes. By fostering a culture of meticulous revision control, teams can significantly improve the efficiency and effectiveness of their automation projects.

Related Posts

-

What is Control Engineering and Why It Matters in Modern Industry

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

How to Master Electrical Control Panel Design for Your Next Project

-

What is the Importance of PLC Programming in Modern Automation

-

The Future of HMI Panel Innovation and Automation