5 Essential Tips for Optimizing Your Pneumatic Control Panel Efficiency

In today's fast-paced industrial environment, the efficiency of your pneumatic control panel can significantly impact overall operational productivity. A well-optimized control panel not only enhances system performance but also contributes to improved safety, reduced downtime, and cost savings. As pneumatic systems play a critical role in various applications—from manufacturing to automation—understanding how to maximize the effectiveness of your pneumatic control panel becomes essential. This guide will provide you with five essential tips that will help you streamline your pneumatic control operations, ensure reliable performance, and achieve optimal results in your facility. With these strategies, you can transform your pneumatic control panel into a more efficient and reliable asset, ultimately driving your business success.

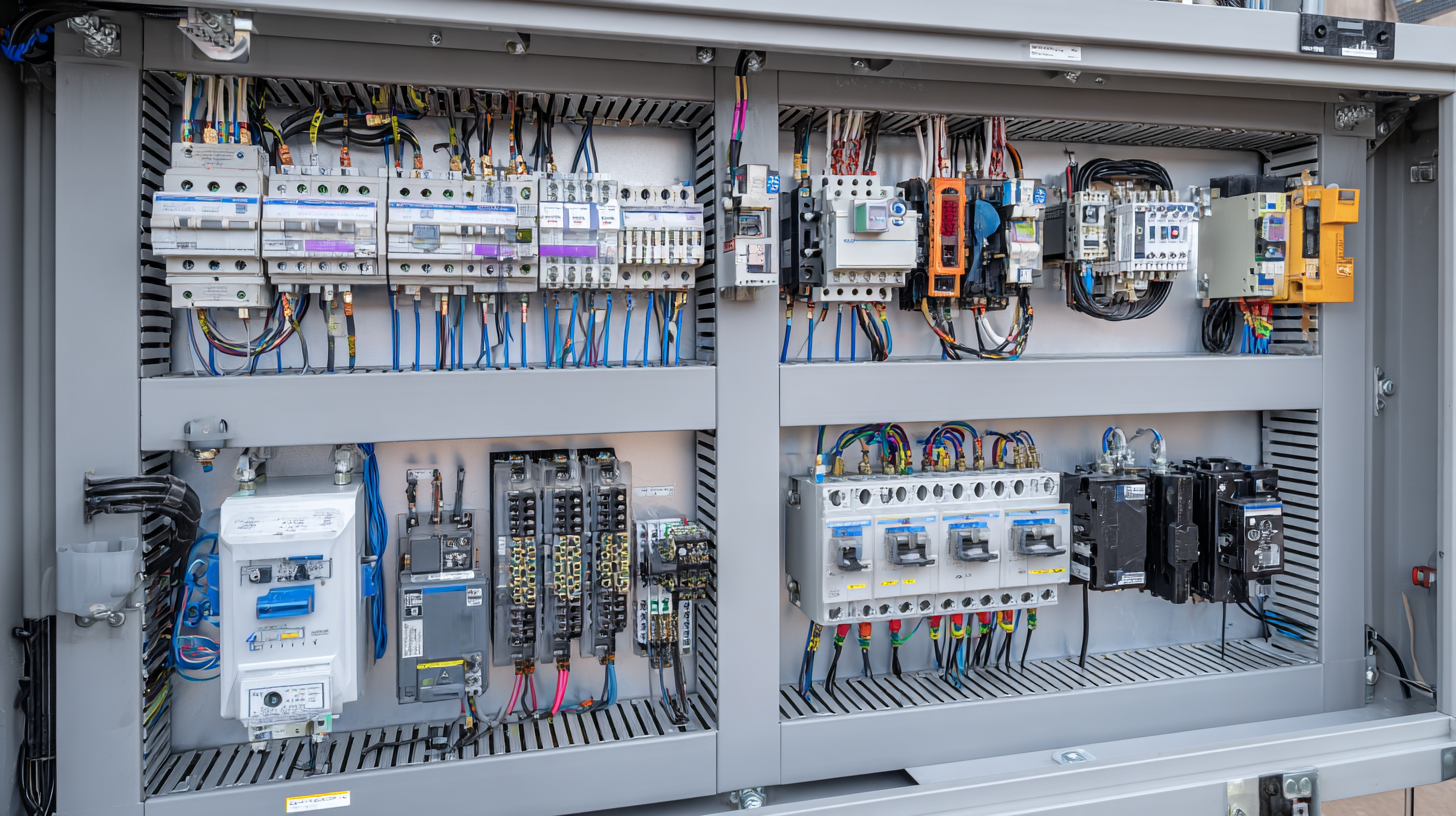

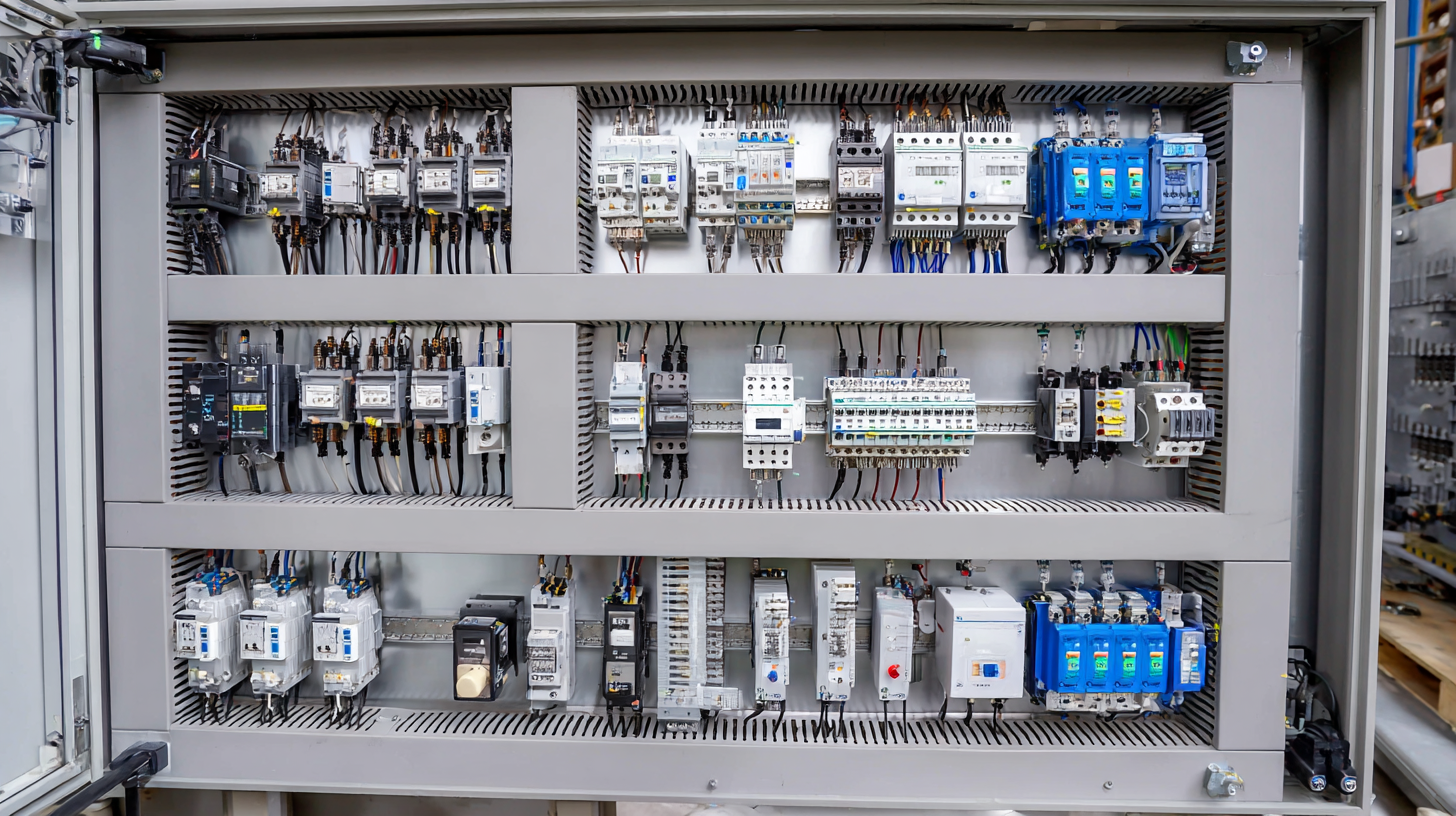

Understanding the Components of Your Pneumatic Control Panel for Better Efficiency

Understanding the components of your pneumatic control panel is crucial for achieving optimal efficiency. A well-structured pneumatic system comprises various elements such as valves, actuators, and pressure regulators. Recognizing how each component functions and interacts with the others allows for better troubleshooting and enhanced performance. For instance, ensure that your valves are correctly calibrated to prevent air leaks, which can lead to significant energy loss.

To further increase efficiency, regularly maintain your pneumatic components. Routine inspections can identify wear and tear before they result in costly downtime. Additionally, using high-quality filters will keep contaminants from interfering with the system’s performance, ensuring a longer lifespan for your equipment.

Finally, implementing automation in your control panel can greatly streamline processes. Automated controls can optimize air usage by adjusting pressure and flow rates in real-time. By minimizing manual intervention, you can improve both response time and accuracy, leading to a more efficient pneumatic control system.

Evaluating and Adjusting Pressure Settings for Optimal Performance

When it comes to optimizing the efficiency of your pneumatic control panel, evaluating and adjusting pressure settings is crucial.

Proper pressure levels directly influence the performance and reliability of pneumatic systems.

If the pressure is set too high, it can lead to increased wear and tear on components, resulting in costly maintenance and downtime.

Conversely, if the pressure is too low, it can hinder the system's functionality, leading to subpar performance and inefficiencies.

Regularly assessing pressure settings ensures that your pneumatic system operates within the ideal range, minimizing potential risks and maximizing output.

To effectively adjust pressure settings, begin by reviewing the manufacturer's specifications and operational requirements for each component within the control panel.

Utilizing precise pressure gauges and monitoring tools can help you identify any discrepancies in the current settings.

Once discrepancies are found, incremental adjustments should be made to achieve the optimal pressure.

Additionally, consider implementing a routine maintenance schedule that includes pressure checks, which will help in maintaining the efficiency of the system and extending its lifespan.

By prioritizing these adjustments, you can enhance the overall performance and reliability of your pneumatic control panel.

Implementing Regular Maintenance Practices to Extend Equipment Lifespan

Regular maintenance is crucial for ensuring the longevity and efficiency of your pneumatic control panel. By establishing a consistent maintenance schedule, you can identify potential issues before they escalate into significant problems. Regular checks should include inspecting hoses for wear, ensuring connections are tight, and testing valve functionality. This proactive approach not only minimizes downtime but also enhances the overall performance of your equipment.

Additionally, incorporating lubrication into your routine can significantly extend the life of moving parts within the control panel. Dirty or insufficient lubrication can lead to increased friction, causing premature wear and tear. Cleaning components and applying the appropriate lubricants at recommended intervals can help maintain smooth operation and avoid costly repairs. Moreover, proper documentation of maintenance activities helps track the health of your equipment and facilitates better planning for future service needs. By committing to regular maintenance practices, you can optimize your pneumatic control panel's efficiency and reduce the risk of unexpected failures.

Leveraging Automation and Smart Technology for Enhanced Control

Leveraging automation and smart technology is crucial for enhancing the efficiency of pneumatic control panels. In an era where industries are increasingly pivoting towards streamlined operations, the integration of advanced technologies can significantly reduce manual errors and improve responsiveness. For instance, implementing programmable logic controllers (PLCs) and sensors grants real-time data monitoring and adjustments, enabling quicker reaction times to fluctuations in pressure or flow. This automation not only optimizes performance but also extends the lifespan of equipment by preventing overload and wear.

Moreover, smart technology enables predictive maintenance, which allows operators to anticipate issues before they escalate into significant problems. By analyzing data trends, such as pressure variations or component wear, businesses can schedule maintenance activities proactively. This minimizes downtime and ensures that the pneumatic control panels operate at their peak efficiency. In addition, cloud-based systems facilitate remote monitoring and control, granting teams the ability to manage operations from anywhere, enhancing both flexibility and productivity in their workflow.

5 Essential Tips for Optimizing Your Pneumatic Control Panel Efficiency - Leveraging Automation and Smart Technology for Enhanced Control

| Tip Number | Tip Description | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Integrate Smart Sensors for Real-time Monitoring | Improved system responsiveness and reduced downtime | Moderate |

| 2 | Utilize Automated Control Systems | Increased precision and reduced labor costs | High |

| 3 | Adopt Predictive Maintenance Techniques | Minimized unplanned service interruptions | Moderate |

| 4 | Implement Data Analytics for Performance Monitoring | Enhanced decision-making based on real data | High |

| 5 | Use User-friendly Interfaces for Operators | Improved operator efficiency and reduced training time | Low |

Training Staff on Best Practices to Maximize System Efficiency

Training staff on best practices is crucial for maximizing the efficiency of pneumatic control panels. According to a report by the International Society of Automation, organizations that invest in comprehensive training programs can witness a 25% increase in overall system efficiency. This highlights the importance of equipping personnel with the necessary skills to operate and maintain pneumatic systems effectively.

One essential tip is to conduct regular training sessions that cover the latest technological advancements and maintenance practices. For instance, emphasizing the significance of proper actuator calibration can lead to improved accuracy and reduced energy consumption. Additionally, familiarizing staff with troubleshooting methods can minimize downtime; a study conducted by the Hydraulic and Pneumatic Institute found that effective training reduced troubleshooting time by up to 40%.

Another crucial point is the implementation of simulation-based training, which has been shown to enhance retention rates and practical skills. A survey by the American Society of Mechanical Engineers indicated that hands-on training results in a 30% higher performance in real-world situations compared to traditional methods. By developing a culture of continuous learning, organizations can ensure their teams are adept at utilizing pneumatic systems, ultimately driving efficiency and productivity.

Optimizing Pneumatic Control Panel Efficiency

This bar chart illustrates the impact of various best practices on the efficiency of pneumatic control panels. The most significant factor is staff training, followed by system maintenance and regular audits. Implementing these practices can lead to better performance and safety.

Related Posts

-

How to Master PLC Controller Programming for Industrial Automation

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

The Future of HMI Panel Innovation and Automation

-

Top Strategies for Effective Distribution Control in Global Supply Chains

-

How to Master Electrical Control Panel Design for Your Next Project

-

What is the Importance of PLC Programming in Modern Automation