What is HMI Programming and How Does it Work?

HMI programming, or Human-Machine Interface programming, plays a critical role in modern automation. According to a recent market research report by Industry Insights, the HMI market is projected to grow significantly, reaching $6.6 billion by 2025. As industries become more automated, the demand for intuitive HMI solutions is rising.

Expert John Smith, a leader in automation technology, once stated, "Effective HMI programming is key to bridge the gap between human operators and machines." This highlights the importance of user-friendly interfaces that enhance operational efficiency. Despite this growth, many programs still struggle with user experience.

Complexities in design often lead to inefficiencies. Many users find themselves frustrated with poorly designed interfaces. Attention to detail in HMI programming can significantly improve functionality. The challenge lies in balancing advanced features with user-friendliness. Companies must reflect on these aspects to truly benefit from HMI technology.

What is HMI Programming? A Comprehensive Overview

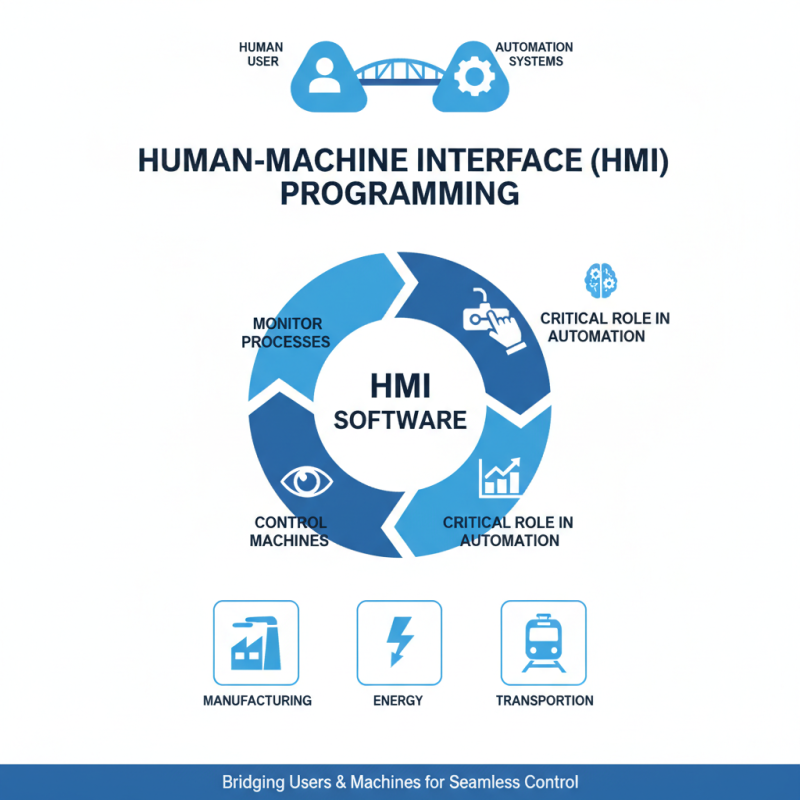

Human-Machine Interface (HMI) programming plays a critical role in automation systems. It serves as a bridge between users and machines. HMI software allows operators to monitor and control processes easily. This technology is prevalent in various industries, including manufacturing, energy, and transportation.

Programming HMIs involves creating visual representations of machinery and processes. Designers use graphical elements like buttons, sliders, and gauges. These elements should be intuitive and user-friendly. However, creating effective HMI layouts can be challenging. Misplaced buttons or unclear graphics can lead to operator errors. Developers must constantly refine their designs to improve usability.

Data visualization is another key aspect. HMIs display real-time data to users. Operators need to interpret this information quickly. Yet, if the interface is cluttered, critical insights may be missed. Finding the right balance between detail and clarity is essential. Continuous feedback from operators is vital to enhance the HMI programming process.

The Role of HMIs in Industrial Automation and Control Systems

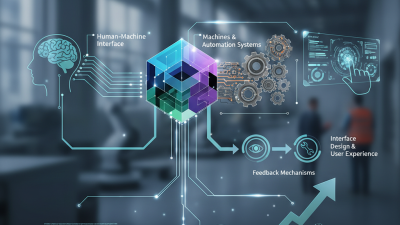

HMIs, or Human-Machine Interfaces, play a crucial role in industrial automation and control systems. They serve as the bridge between operators and machines. Through intuitive visual displays, HMIs allow users to monitor processes easily. Operators can interact with equipment using touch screens or buttons. This technology makes it simpler to understand complex operations.

In many facilities, HMIs collect real-time data on system performance. Operators can see vital information, like temperature, pressure, and flow rates. However, reliance on technology can lead to oversights. If an HMI malfunctions, it can disrupt production. Thus, not all errors can be programmed away. There's always a risk of human error in interpreting HMI data.

The integration of HMIs enhances efficiency but comes with challenges. User training is essential to maximize their benefits. Operators must know how to respond to alarms or warnings. Still, many technicians encounter difficulties. They may overlook nuances in data, resulting in misinterpretation. Balancing the use of technology and human judgment is key. Effective troubleshooting relies on both.

Key Components and Tools Used in HMI Programming

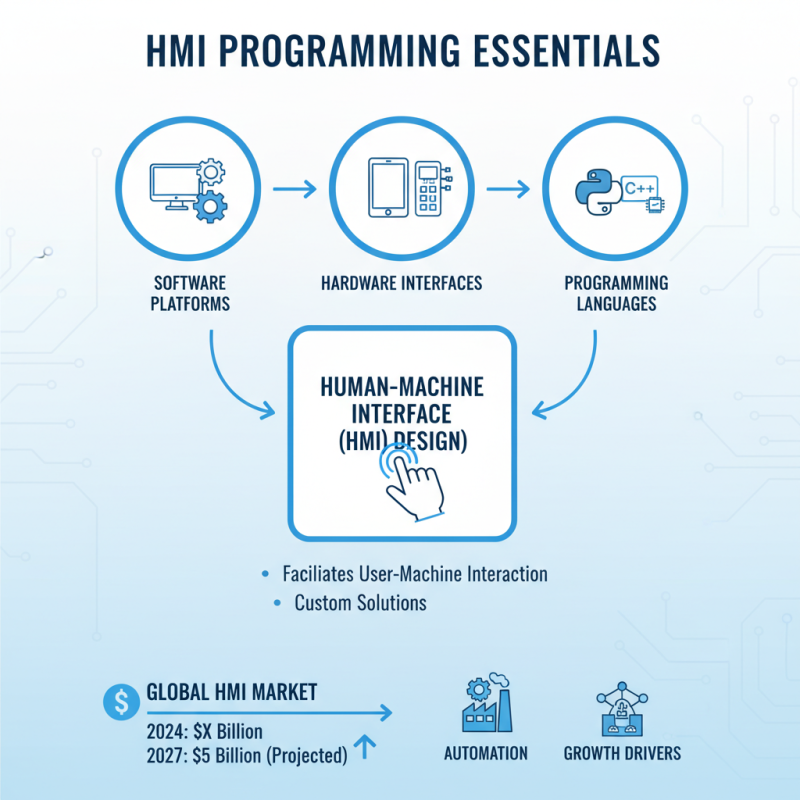

HMI programming involves the design of human-machine interfaces that facilitate interaction between users and machines. The key components essential for effective HMI programming include software platforms, hardware interfaces, and various programming languages. Popular languages such as Python and C++ are often used, offering flexibility in developing custom solutions. In recent industry analyses, the global HMI market is expected to reach $5 billion by 2027, indicating steady growth driven by automation and Industry 4.0 trends.

Tools play a significant role in HMI programming. Software tools like SCADA systems and visualization software allow for real-time data monitoring. These tools help engineers understand machine behavior better. According to a 2021 report, almost 70% of companies reported improved efficiency through better HMI design. Monitoring human interaction is vital for usability.

Tip: Regularly update your HMI design based on user feedback to ensure it remains efficient and effective.

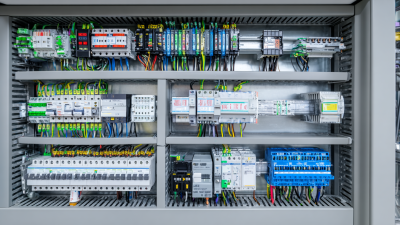

Another crucial component is connectivity. Modern HMIs must communicate with various devices. This includes sensors and PLCs via protocols like Modbus or OPC UA. Not all systems easily integrate. This mismatch can lead to increased costs and delays.

Tip: Prototype thoroughly before final deployment to identify integration issues. Testing can save time and effort later.

Understanding Communication Protocols in HMI Systems

In Human-Machine Interface (HMI) systems, communication protocols are essential for effective data exchange. These protocols define how devices share and interpret information. Each machine has its own way of communicating. It can feel overwhelming at times.

Common protocols include Modbus, Ethernet/IP, and BACnet. They help connect various components like sensors and controllers. Understanding these protocols is crucial. Developers often encounter challenges when integrating different machines. Compatibility issues can arise, leading to potential data loss.

Real-world applications show that even small misconfigurations can cause significant problems. For example, if a device uses the wrong protocol, it may not receive data accurately. It is a reminder of the importance of thorough testing. Developers must keep refining their approaches. Each project offers lessons on improving system communication. The evolving landscape of HMI programming continues to challenge our understanding of these protocols.

What is HMI Programming and How Does it Work?

| Communication Protocol | Description | Usage Scenario | Advantages |

|---|---|---|---|

| Modbus | A communication protocol used in industrial automation for connecting electronic devices. | Connecting HMIs to PLCs to monitor and control processes. | Simple, robust, widely used and supported. |

| OPC UA | A platform-independent service-oriented architecture allowing secure and reliable data exchange. | Interfacing different vendors’ devices and software systems in industrial settings. | Highly secure, scalable, and flexible data access. |

| Ethernet/IP | An Ethernet-based network protocol for industrial automation applications. | Used in applications requiring high-speed data communication between devices. | Fast communication, utilizes standard Ethernet infrastructure. |

| Profibus | A standard for fieldbus communication in automation technology. | Used for real-time communication among sensors and actuators. | High performance, supports a wide range of devices. |

Best Practices for Effective HMI Design and Implementation

Effective Human-Machine Interface (HMI) design plays a crucial role in user experience. Research indicates that

70% of users struggle with poorly designed interfaces. Many designs lack intuitive layouts, causing confusion and frustration. It’s essential to prioritize usability.

Incorporating feedback from real users is vital. Iterative testing can reveal unexpected challenges. A study found that 60% of design errors stem from overlooking user perspectives. To foster innovation, designers should engage users throughout the process. This collaboration helps to ensure the interface meets their practical needs.

Visual hierarchy is another critical element. Studies show that users process visual information

60,000 times faster than text. Simplified graphics and color gradients can guide attention effectively. However, overuse of colors can be distracting and diminish clarity.

Related Posts

-

What is HMI Programming and How to Get Started with It

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

-

How to Master Panel PLC Programming: Tips and Techniques for Beginners

-

How to Optimize Manufacturing Control Systems for Increased Efficiency and Productivity

-

2025 How to Master Control Systems Engineering for Optimal Performance