Essential Guide to Mastering PLC Controller Programming Techniques

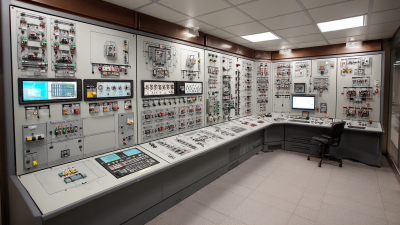

In the realm of industrial automation, mastering PLC controller programming is vital for professionals looking to enhance their skills and improve system efficiencies. Whether you are a novice seeking to grasp the fundamentals or an experienced technician aiming to refine your techniques, this essential guide offers a comprehensive overview of PLC programming methods and strategies. We will delve into crucial tips that cover everything from basic logic to advanced troubleshooting, providing you with the tools necessary to optimize your programming abilities. With the right knowledge and practical insights, you can effectively harness the power of PLC technology, ensuring seamless operations and innovative solutions in various industrial applications. Join us as we explore the fundamental and advanced aspects of PLC controller programming that can elevate your expertise and propel your career forward.

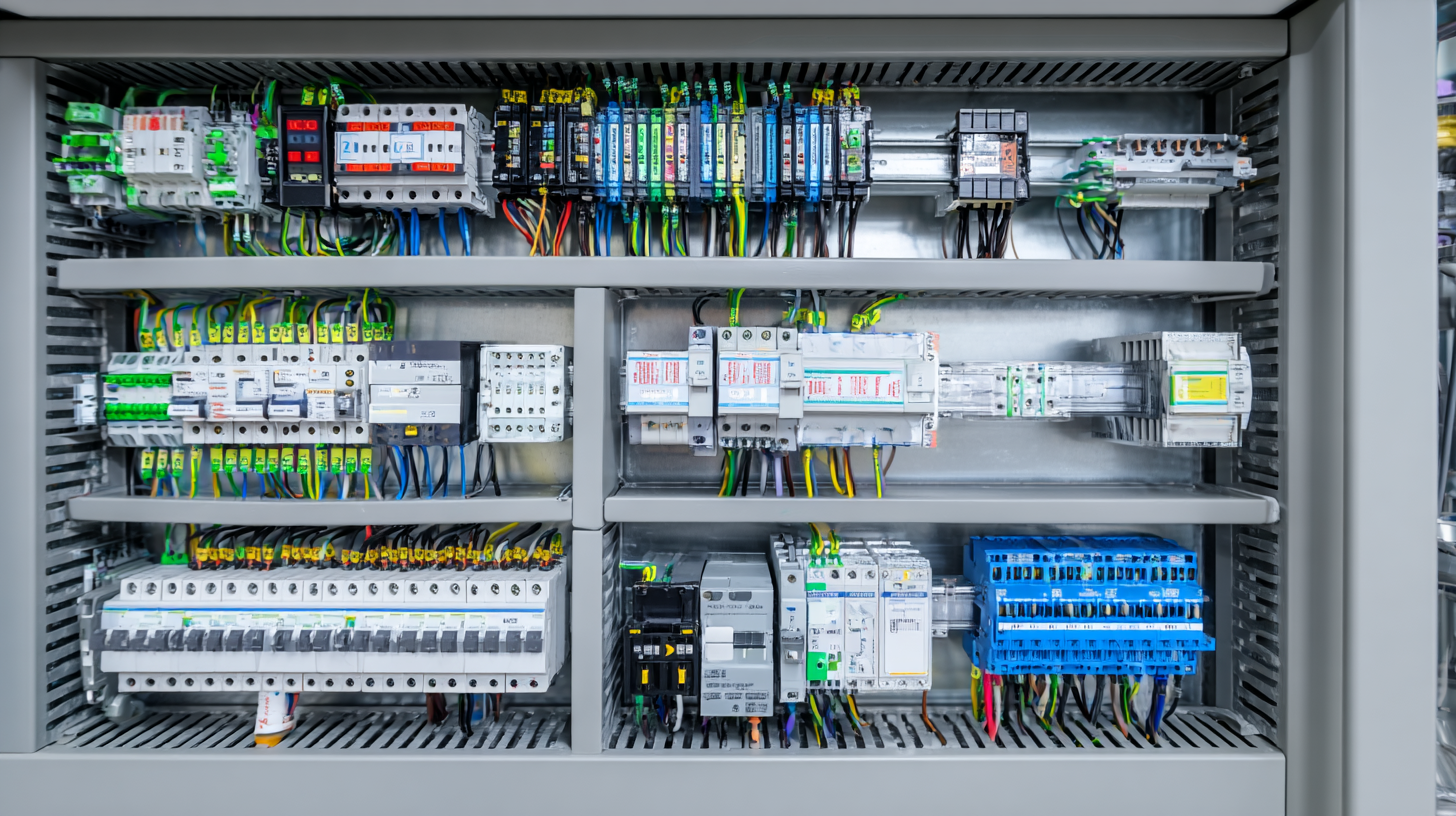

Understanding the Basics of PLC Controllers: Key Concepts and Functions

Programmable Logic Controllers (PLCs) are indispensable components in modern industrial automation. As industry demands evolve, understanding the basics of PLC controllers, including their key concepts and functions, becomes essential for engineers and technicians alike.

According to a recent industry report, the PLC software market is set to be valued at $13.99 billion by 2025, with a robust compound annual growth rate (CAGR) of 11.08% projected through 2033. This growth reflects the increasing reliance on automation technologies across various sectors.

The recent push by domestic PLC manufacturers in China aims to harness this growth potential, as highlighted by the launch of a new aggregation platform strategy intended to unify various PLC brands in the country. This initiative seeks to address current market shortcomings and collaboratively build influential homegrown PLC brands. With the rapid expansion of the industrial software sector, this represents a historic opportunity for domestic PLC manufacturers to thrive, innovate, and contribute significantly to both local and global markets.

Exploring Different Types of PLC Programming Languages and Their Applications

Programmable Logic Controllers (PLCs) have revolutionized automation in various industries, making it crucial for professionals to understand different programming languages and their applications. Primarily, there are five main types of PLC programming languages: Ladder Logic, Function Block, Structured Text, Instruction List, and Sequential Function Charts. Each language has its unique strengths, catering to different project requirements and complexity levels.

Ladder Logic is widely used due to its graphical representation resembling electrical relay logic, making it accessible for engineers with background knowledge in electrical systems. Function Block Diagram, on the other hand, is ideal for complex control systems, allowing users to create reusable blocks for specific functions. Structured Text provides a high-level programming approach, similar to traditional programming languages like Pascal, making it suitable for mathematical computations. Instruction List and Sequential Function Charts, though less common, offer efficient solutions for specific automation tasks by using unique representations for processes and sequences. Understanding these languages and their applications gives professionals the tools to select the most effective programming approach for their specific automation challenges.

Essential Techniques for Effective Ladder Logic Programming

Ladder logic programming remains a cornerstone in the automation industry, frequently utilized for programming PLCs (Programmable Logic Controllers). According to a report by MarketsandMarkets, the global PLC market is expected to grow from USD 9.07 billion in 2020 to USD 12.18 billion by 2025, showcasing the increasing reliance on these systems. By mastering effective ladder logic programming techniques, engineers can significantly enhance system efficiency and reliability.

One key technique in ladder logic programming is the use of structured programming principles, which align with best practices advocated by organizations such as the International Society of Automation (ISA). The ISA emphasizes the importance of modular code and reusable function blocks to facilitate maintenance and upgrades. For example, employing the modular approach can reduce programming time by up to 30%, as indicated by research from the Automation Research Institute. Additionally, leveraging simulation tools during the programming phase can help identify potential issues before deployment, further streamlining the development process and mitigating costly errors in live environments.

Advanced PLC Programming Approaches: Structured Text and Function Block Diagrams

In the realm of industrial automation, mastering advanced PLC programming techniques such as Structured Text (ST) and Function Block Diagrams (FBD) is increasingly essential for engineers and developers. According to a report by the International Society of Automation (ISA), structured programming methodologies account for over 60% of effective automation implementations, highlighting the importance of proficiency in ST and FBD. These languages provide a high-level, readable format that allows engineers to write complex algorithms with greater ease and flexibility, making it simpler to troubleshoot and optimize systems in real time.

Structured Text is particularly beneficial for applications requiring intricate control logic, enabling users to incorporate conventional programming constructs like loops and conditionals. On the other hand, Function Block Diagrams facilitate a visual representation of processes, allowing for easier comprehension and modification, critical in collaborative environments. A survey conducted by Automation.com revealed that 78% of automation professionals believe that the use of FBD aids significantly in enhancing productivity and reducing downtime. By refining skills in both ST and FBD, professionals can drive efficiency and innovation in their PLC programming endeavors, positioning themselves at the forefront of industrial technology advancements.

Common Challenges in PLC Programming and How to Overcome Them

When diving into PLC programming, practitioners often encounter several common challenges that can hinder their progress. One prevalent issue is the understanding of ladder logic, the primary programming language for PLCs. Many new programmers struggle to visualize how the logic flows and how individual components interact within a rung of a ladder diagram.

**Tip:** To overcome this, it's useful to break down complex processes into smaller, manageable segments. Sketch each part on paper or use simulation software to visually represent the logic as you develop it piece by piece. Practicing with real-life scenarios can significantly enhance comprehension.

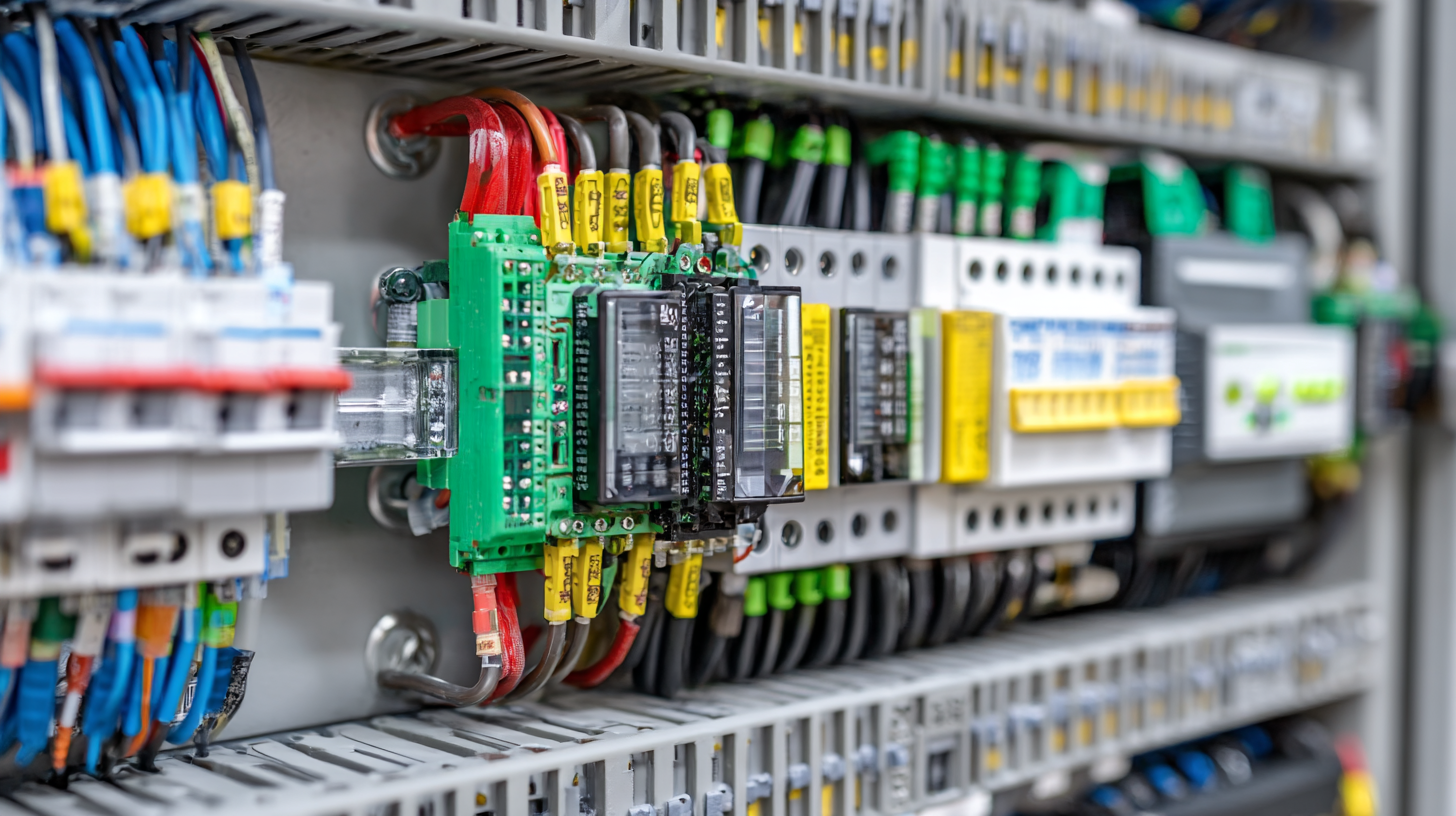

Another challenge is managing system integration with other devices and networks. Ensuring that the PLC communicates effectively with sensors, actuators, and HMI systems can often lead to frustrating troubleshooting sessions.

**Tip:** Keep a detailed documentation of your system architecture, including communication protocols and wiring diagrams. This practice not only helps in troubleshooting but also serves as a valuable reference for future updates or modifications. Collaboration with colleagues who have experience in industrial automation can also provide insights and expedite problem-solving.

Essential Guide to Mastering PLC Controller Programming Techniques - Common Challenges in PLC Programming and How to Overcome Them

| Challenge | Description | Solution |

|---|---|---|

| Lack of Clear Requirements | Unclear specifications can lead to improper programming and unexpected outcomes. | Engage with stakeholders to define clear and specific requirements before starting programming. |

| Insufficient Testing | Failure to adequately test code can result in defects and failures in the field. | Implement a thorough testing protocol, including simulation and real-world testing. |

| Complex Code Structure | Overly complicated code can be difficult to read and maintain. | Use modular programming techniques and thorough documentation to enhance clarity. |

| Insufficient Knowledge of PLC Functionality | Not understanding the PLC's capabilities can lead to ineffective programming. | Conduct regular training and stay updated on new features and capabilities of the PLC. |

| Communication Gaps | Poor communication among team members can lead to errors and misunderstandings. | Encourage open communication and regular meetings to align on project goals. |

Related Posts

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

How to Master PLC Controller Programming for Industrial Automation

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility

-

What is the Importance of PLC Programming in Modern Automation

-

How to Master Electrical Control Panel Design for Your Next Project

-

7 Essential Tips for Creating the Best Control Panel Drawings in Industrial Automation