How to Optimize Your Manufacturing Efficiency with VFD Control Panels

In the ever-evolving landscape of manufacturing, optimizing efficiency is paramount for staying competitive. A recent report from the National Institute of Standards and Technology indicates that energy efficiency improvements in manufacturing could save the industry over $1 billion annually. One crucial advancement in achieving this efficiency is the utilization of VFD control panels. These panels not only enhance energy saving by regulating motor speeds according to load demands, but they also improve process control and equipment longevity.

By integrating VFD control panels, manufacturers can significantly reduce operational costs while simultaneously boosting productivity. As industries increasingly recognize the strategic value of efficiency, understanding how to effectively implement and optimize VFD control panels becomes essential for achieving sustainable growth and operational excellence.

Benefits of Using VFD Control Panels in Manufacturing Processes

VFD (Variable Frequency Drive) control panels have become essential in optimizing manufacturing processes. One of the primary benefits is energy efficiency. By adjusting the speed of motors according to real-time demand, VFDs minimize energy waste, significantly reducing operational costs. This not only translates into immediate savings but also enhances equipment longevity since motors are under less stress, leading to reduced maintenance requirements.

To maximize the advantages of VFD control panels, it is crucial to conduct a thorough assessment of your existing systems. Start by identifying areas where energy consumption is highest and determine if VFDs can be integrated. Additionally, consider implementing advanced control strategies that adapt to changing production demands. This proactive approach will ensure that your machinery operates at peak efficiency, reducing downtime and increasing overall productivity.

Regular training for staff on VFD functionalities can also enhance performance. Equip your team with the knowledge to utilize these systems effectively, ensuring that they can adjust settings as needed based on production requirements. By fostering a culture of efficiency, your manufacturing processes will not only optimize energy use but also improve output quality.

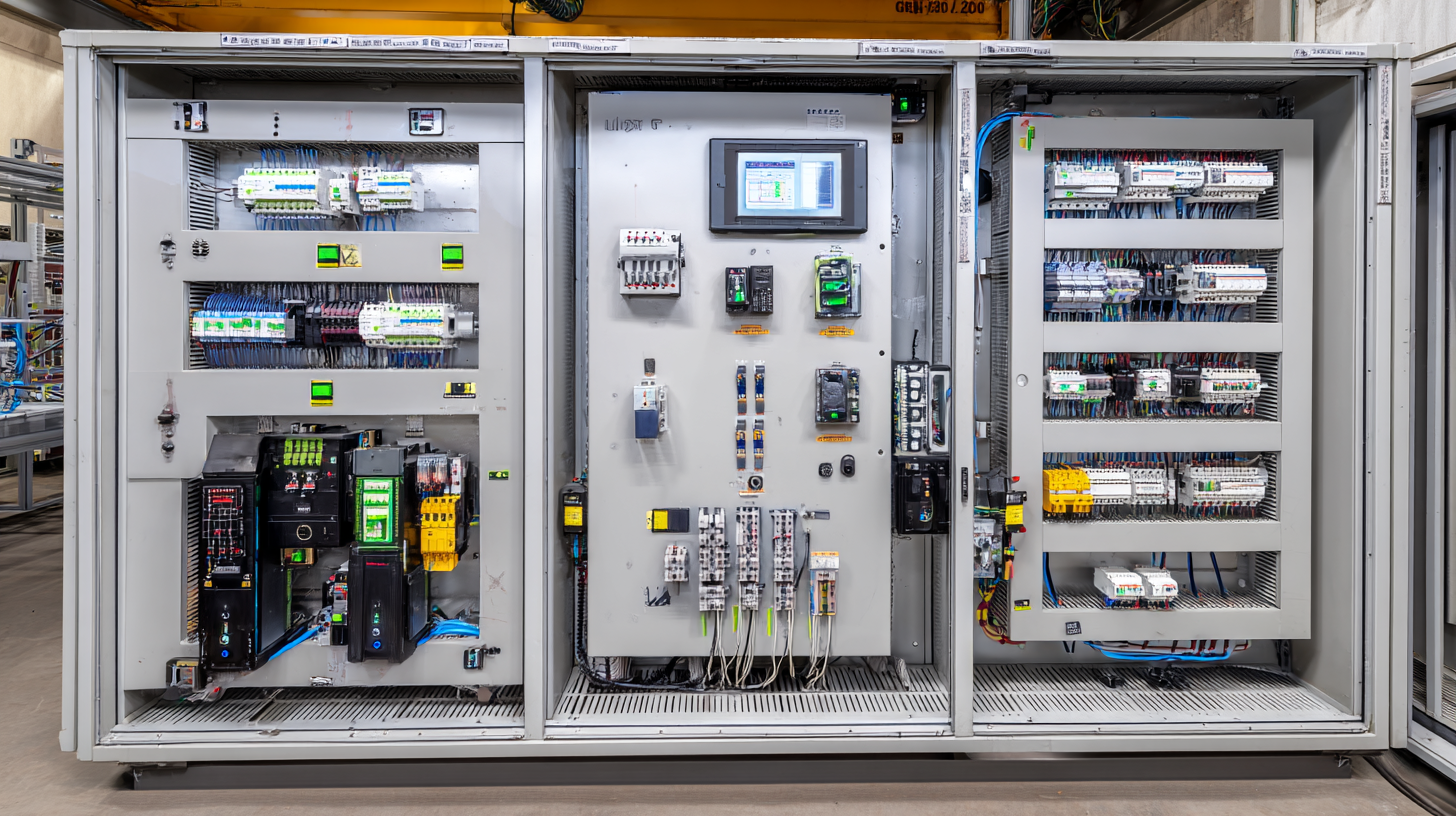

Manufacturing Efficiency with VFD Control Panels

Key Features of VFD Control Panels That Enhance Efficiency

VFD (Variable Frequency Drive) control panels are essential for optimizing manufacturing efficiency. These panels enhance efficiency through their ability to adjust motor speed and torque according to load requirements. One of the key features is the energy-saving capability, which allows for precise control of the output performance, reducing energy consumption significantly. Factories can see immediate savings on electricity costs while also extending the lifespan of the equipment.

Another critical feature is the integration of advanced monitoring systems. These systems provide real-time data on operational performance and allow manufacturers to anticipate maintenance needs proactively. By using predictive maintenance techniques, companies can avoid unexpected downtimes, thus keeping production lines running smoothly.

**Tip:** To maximize the benefits of VFD control panels, consider investing in training for your staff. Proper understanding of how to operate and maintain these systems can lead to more effective use and further enhance production efficiency. Regularly reviewing system performance data can also lead to insights that streamline operations.

Best Practices for Integrating VFD Control Panels into Existing Systems

Integrating Variable Frequency Drive (VFD) control panels into existing manufacturing systems can significantly enhance efficiency and performance. To begin, it's essential to conduct a thorough assessment of your current machinery and processes. Identify specific areas where motor control can be optimized—this might include operations that involve varying speeds, loads, or torque requirements. By understanding the unique demands of your system, you can select the appropriate VFD models that will seamlessly integrate without causing disruptions.

Once the right VFDs are chosen, consider implementing a staged approach to integration. Start by installing VFDs on less critical equipment to evaluate their impact on system performance. Monitor key performance indicators such as energy consumption, output quality, and operational uptime throughout this pilot phase. This data will provide crucial insights that can guide further integration across other machinery. Additionally, ensure that personnel are well-trained on the new systems to maximize their potential and troubleshoot any issues that may arise during the transition. Effective communication between teams will foster a smoother integration process and ultimately lead to enhanced manufacturing efficiency.

Common Mistakes to Avoid When Implementing VFD Technology

When implementing Variable Frequency Drive (VFD) technology, it is crucial to avoid common pitfalls that can hinder manufacturing efficiency. One key mistake is neglecting proper training for staff. Without a thorough understanding of how VFDs operate, employees may not utilize the technology to its fullest potential or may even misconfigure settings. Investing in training sessions or workshops can significantly enhance the proficiency of your team.

Another common error is ignoring the importance of system compatibility. Before installing VFD control panels, ensure that all components of the machinery are compatible. Incompatible systems can lead to operational inefficiencies and even equipment damage. Conduct a thorough assessment of your existing systems and consider consulting with experts to ensure seamless integration.

Lastly, failure to monitor performance post-installation can result in lost opportunities for optimization. Regularly reviewing the performance metrics of VFDs allows you to identify areas for improvement and allows for timely adjustments. Set up a performance monitoring system to keep track of energy consumption and output effectiveness, helping you maintain peak efficiency and avoid costly downtime.

Future Trends in VFD Control Panel Technologies for Manufacturing

In the evolving landscape of manufacturing, Variable Frequency Drive (VFD) control panels are becoming essential tools for optimizing efficiency and productivity. The technology behind VFDs is rapidly advancing, with future trends indicating significant growth in the market. By 2025, the global VFD market is projected to reach a revenue of $24.68 billion, further escalating to $32.00 billion in the subsequent years. This growth is driven by increased demand for energy efficiency and automation in manufacturing processes.

As the medium voltage drives market is also expected to grow from $1.81 billion in 2025 to $2.63 billion by 2035, manufacturers must keep an eye on emerging technologies. One key trend is the integration of smart features into VFD control panels, allowing for real-time monitoring and data analysis. These advancements can help optimize equipment performance and reduce operational costs significantly.

**Tip:** Invest in training for your staff on the latest VFD technologies to ensure they leverage the full potential of the equipment.

Additionally, consider employing predictive maintenance strategies enabled by VFD analytics to preemptively address potential issues and enhance system reliability. By staying updated with these trends and implementing strategic improvements, manufacturers can dramatically enhance their operational efficiencies.

Related Posts

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

What is the Importance of PLC Programming in Modern Automation

-

What is Control Engineering and Why It Matters in Modern Industry

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

The Future of HMI Panel Innovation and Automation